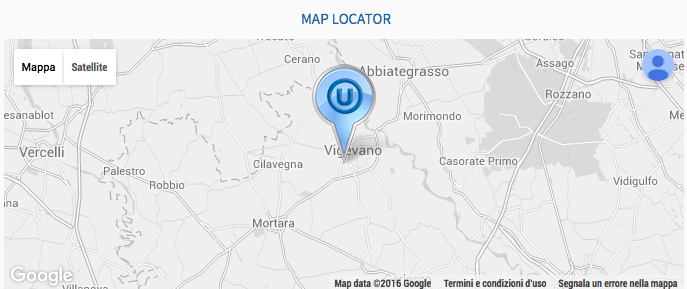

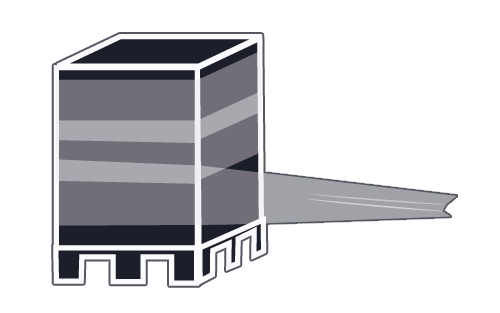

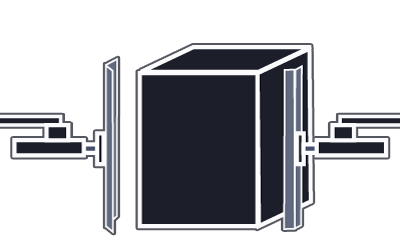

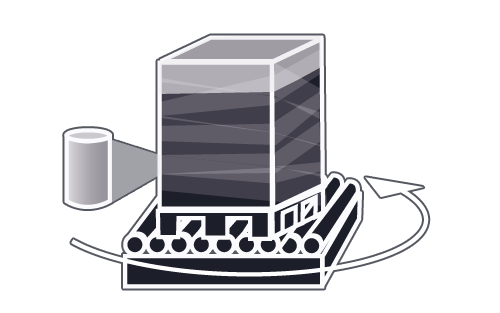

Fully automatic pallet wrapping machine mod. UNIWRAP 300 AVDB (High Speed Configuration with Double Arm) performing stretch wrapping by arm rotation

MECHANICAL FRAME:

- Main steel made frame painted with anti-corrosive coating and epoxy paint in several layers

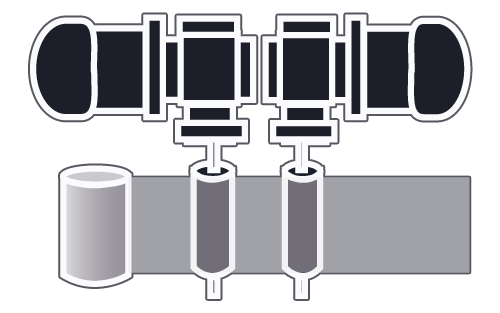

- Double rotating arm supported by main central bearing

- Steel made double arm complete with “U” guides for upstroke / downstroke of the reel carrying unit

OPERATIONAL FEATURES:

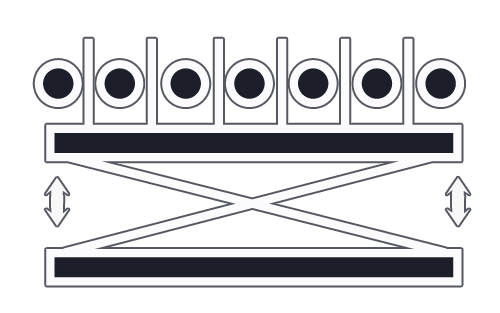

- Soft start and soft stop of the rolls conveyor controlled by inverter

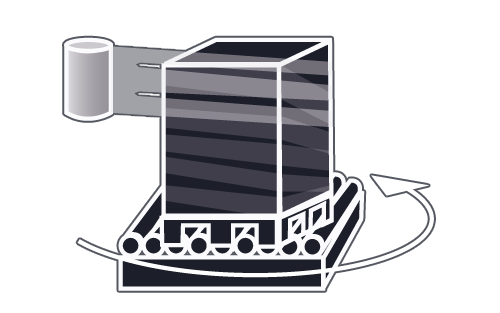

- Electronic adjustable rotation speed of the rotary arm controlled by inverter

- Electronic adjustable upward/downward speed of the pre-stretch unit controlled by inverter. These speeds may have different parameters in order to have maximum flexibility in the settings of the required wrapping cycle

- Photocell for automatic pallet height detection

- Adjustable number of revolutions at the top and bottom of the palletised load

- Device for automatic longitudinal pallet centering in wrapping position

- Device for controlling film tension directly from the operating panel

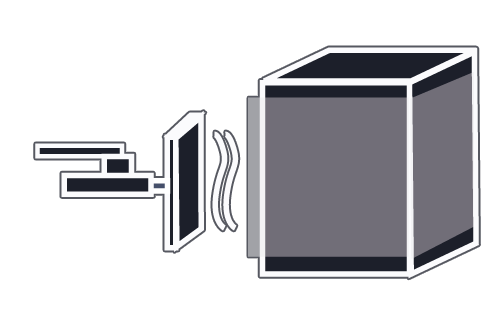

- Electronic control of end/breaking of the stretch-film on the pallet wrapper and of the PE film on the top sheet dispenser

- Program for pallet wrapping exclusion

- Timer for the overlap of the stretch film on the top of the palletised load

- The machine includes double group of film gripper, cutting arm, brush to stick the stretch film to the side of the pallet and all the useful devices to perform a fully automatic working cycle

- Control by P.L.C.

- Operating panel complete with digital display and keyboard to control:

- autodiagnosis program and visualisation of the alarms

- selection of manual operations

- settings of the wrapping cycle

- The machine is supplied with CE standards certification

- Productive capacity 150 pal/h

SOLUTIONS

Powered pre-strech with variable ratio

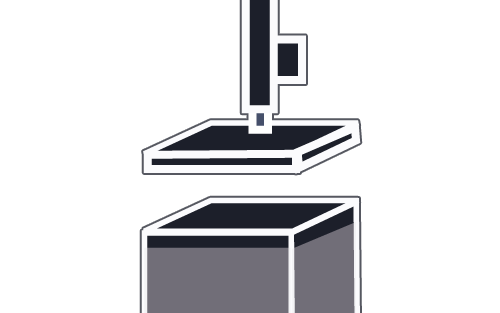

Pneumatic / mechanical top pressor for light or unstable products

Pneumatic tension control

Electric welding

Hydraulic lifter

Fully automatic system to apply cornerboard to protect the edges of the pallet

Device to reduce stretch film height

Device to cut stretch film width into 3 stripes