-

Unitech will participate in Propak Asia 2023

Propak Asia is one of the leading international trade fairs for the packaging and processing industry, attracting exhibitors and visitors from all over the world.

As an innovative company in this field, we are excited to announce our participation in this year's event, which will be held from June 14th to 17th in Bangkok, Thailand.

At our booth D36, we will showcase our latest solutions. Our team of experts will be available to answer any questions and provide demonstrations of our products and services. We are committed to sustainability and eco-friendly practices, and we will emphasize this aspect of our business at Propak Asia.

We believe it is important for companies in the packaging and processing industry to take responsibility for their impact on the environment, and we are proud to be at the forefront of this effort. We are excited to network with other industry professionals at Propak Asia and learn about the latest trends and innovations in the packaging industry.

This event is an important platform to showcase our products and services and to connect with potential clients and partners. Participating in Propak Asia 2023 is therefore a great opportunity to present our latest products and solutions. Do not miss this exciting opportunity to connect with us and discover how we can help your company grow. Come and visit us at booth D36!

-

Unitech will participate in Interpack Düsseldorf 2023

Unitech is pleased to announce its participation in Interpack, the world's leading trade fair for packaging innovations across the entire value chain, highlighting key trends in the industry.

The event will be held in Düsseldorf and represents a unique opportunity for us to showcase our latest packaging solutions and technologies to a global audience. For years, our company has specialized in providing packaging solutions for various sectors, ranging from food and beverage to chemical, manufacturing, pharmaceutical, cosmetics, industrial goods, and many more.

In Düsseldorf, we will be presenting the latest generation of packaging machines and related process technologies that we have worked on for months to ensure they meet the highest standards of quality, efficiency, and sustainability.

We're aware that Interpack is not just an ordinary trade fair, but a trendsetter for future industry themes, from sustainability to digitization. For this reason, we are excited to present our latest packaging solutions that align with these future themes. Our goal is to demonstrate how our innovative products and technologies can help our customers reduce their environmental footprint and streamline their operations through digitization.

As a company that values sustainability, we are pleased to participate in Interpack to discuss the latest trends and solutions for a sustainable future.

We believe that Interpack offers an excellent platform to connect with industry leaders, exchange ideas, and explore new collaboration opportunities. Our participation reflects our commitment to providing innovative and sustainable packaging solutions to our customers.

We look forward to showcasing our latest products and technologies at this global event, and we are confident that our participation will enable us to make meaningful connections with other industry players, ultimately contributing to the growth and success of our company.

-

Unitech's app for packaging planning now available

Unitech's app for packaging planning now available

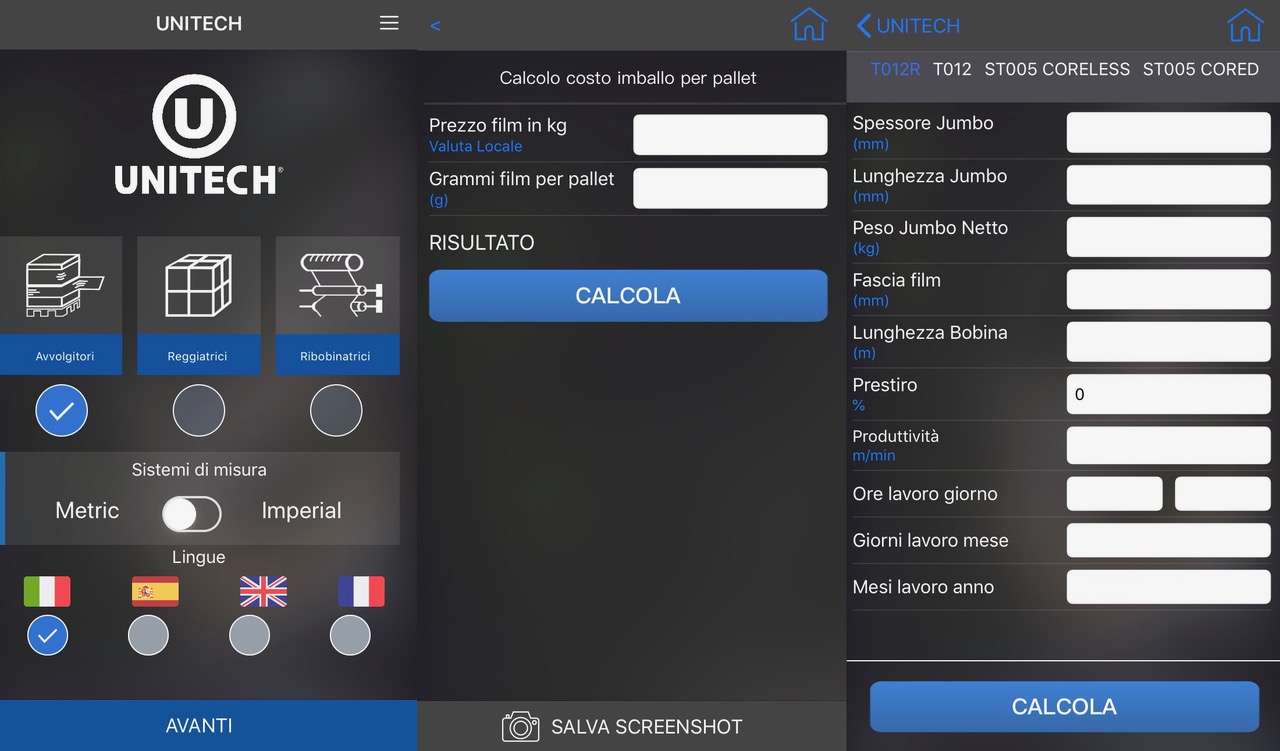

The Unitech mobile app for packaging systems is now available for download on the AppStore for iOS. In an effort to enable partners to make all the calculations needed to plan their production, costs and raw material consumption, Unitech now provides a perfect complement to its automatic packaging systems.

This is the result of a 4.0 mindset that go beyond the usual approach in integrating new systems and technology.

Regarding the range of automatic pallet wrappers, the app can calculate:

-Roll weight

-Film weight per pallet

-Film thickness

-Packaging cost per pallet

-Prestretch percentage

-Pallets per roll

-Final packaging costThe pallet strappers section can calculate the cost per pallet according to the parameters used and dimensions.

The section concerning automatic rewinders can give an overview of the whole production starting from observable parameters and productivity, calculating:

-Number of reels produced

-Net seconds to produce a reel

-KGs of finished product

-KGs produced per day, month and year

-Single roll cost

-Depreciation of investment -

Automatic Corner Protection Application on Unitech Packaging Machines

Not all pallets are created equal. Some of them need a higher degree of protection than others, due to their value, importance or physical properties. Nevertheless, adding more protection should not have a significant impact on production times. This is why Unitech, relying on its expertise in the development of custom solutions for the packaging industry, decided to integrate corner protection application as part of the functionality of its automatic packaging machines.

The company’s automatic pallet wrappers and strapping systems can be fitted as an option with dedicated corner or edge protection application devices, adding paper or plastic reinforcements to the loads, which can dramatically increase the level of protection while keeping timing and productivity under control. Unitech can integrate applicators for horizontal or vertical, long or short corner boards.

Protection can be further improved with a top cover applicator, also available on Unitech’s packaging systems. Top covers (plastic or cardboard) can provide with an added layer of safety, making the load dust-proof or waterproof (plastic only). -

Automatic packaging technologies on display in Mexico and Thailand

From one side of the world to the other, Unitech keeps showcasing its best technology. The company will be exhibiting in Latin America and Asia in the first half of June. On June 11th to 13, Unitech will promote its automatic packaging systems in Guadalajara, Mexico, at Expo Pack 2019, specifically at stand #4118.The focus will be, as always, on the automatic wrappers and strapping machines lines, but rewinding will take the centre stage with the introduction of the new UPI Remote monitoring technology, providing a step into Industry 4.0.Almost at the same time, we will be in Bangkok Thailand, from June 12th to 15th at Propak Asia. Unitech will be welcoming interested parties at Stand BR25 in Hall 103.

-

Unitech Packaging premieres cutting-edge 4.0 cloud interface

Unitech is set to take a new, powerful step, in the Industry 4.0 world by introducing the brand-new UPI Environment, which will come as an option on the new automatic rewinding machines and is set for further development in other types of machinery.

UPI (User PLC Interface) is a cloud-based monitoring and scheduling environment that can collect production data from the machines and schedule events throughout their lifespan. As an additional feature, UPI can also manage video streams: using an IP Camera installed inside the machine, and Unitech's remote assistance capabilities, support can reach the next level, reducing downtimes and maintenance costs.With UPI, Unitech customers can:

- monitor the production in real time

- quickly visualize the KPI (key performance indicators)

- locate the position of every machine in the fleet

- download extremely detailed production reports including daily and monthly summaries, standby times

- analyze alarms and potential warnings and other events

- schedule maintenance checks

- use internal video to speed-up the diagnostic and maintenance process

It only takes an internet connection, and an ethernet cable. A powerful micro-computer is then installed in the machine and it connects to the cloud database using a SSH/TLS protocol. The information can be accessed via an online computer interface or downloaded in database form.

The system was developed for Unitech by Firewall Information Technology, a cutting-edge IT provider, and is based on the latest big data-ready database technology.

-

Unitech to release mobile app for packaging planning

A mobile app for your packaging systems? Unitech got that covered. In an effort to provide even more efficiency, ease of use, and cost effectiveness, the Italian manufacturer is preparing to release a ground-breaking application that will enable partners to make all the calculations needed to plan their production, costs and raw material consumption.This is the result of a 4.0 mindset that go beyond the usual approach in integrating new systems and technology.Regarding the range of automatic pallet wrappers, the app can calculate:-Roll weight-Film weight per pallet-Film thickness-Packaging cost per pallet-Prestretch percentage-Pallets per roll-Final packaging costThe pallet strappers section can calculate the cost per pallet according to the parameters used and dimensions.The section concerning automatic rewinders can give an overview of the whole production starting from observable parameters and productivity, calculating:-Number of reels produced-Net seconds to produce a reel-KGs of finished product-KGs produced per day, month and year-Single roll cost-Depreciation of investmentThe Unitech application will be available soon for iOS through the Apple AppStore. The Android version will follow.

-

Remote assistance now available for automatic range

Industry 4.0, here we come. In a world that is rapidly evolving, Unitech has embraced digitalization and all the most valuable new trends in terms of making its customers' production more efficient, straightforward and competitive every day. All Unitech machines are able to benefit from a remote assistance module to simplify software intervention and upgrade.With this option, customers will receive software assistance straight from the company's headquarters in Vigevano. The module is available for the full range of stretch film rewinders, automatic pallet strappers and automatic stretch wrappers. The option to have a PLC with remote assistance is available for the semi-automatic Uniwrap 100 line too.There is more to come, as a ground-breaking cloud-based monitoring environment is undergoing testing to be soon implemented of the range of automatic rewinders with the goal of expanding it to the whole production.More news and updates will come in due time, as Unitech continues to push forward in a world dominated by technical advancements.

-

Unitech draws a balance for the end of 2018

It's been a busy end of 2018 for Unitech as the company continues to focus on research and development while showcasing its technology in the world's most outstanding exhibitions. As Operations Manager Paolo Battista explains, "There has been a huge turnout, especially at the Pack Expo Exhibition in Chicago, where potential customers proved extremely interested in the innovation proposed. In addition, we had a positive experience at the Plastic & Rubber Indonesia exhibition were we finalized the partnership with local producer Goldenswan, which will introduce the next-gen pre-stretch coreless film by Unitech in the South Eastern Asian market.”"Concerning our line of automatic pallet wrappers, there was great interest towards our latest upgrade, a film banding lowerator controlling the film's position during the wrapping process. That enables to reinforce the edges in any moment of the process and can even create a roping effect to further increase load stability. It’s also possible to revert back to the standard wrapping immediately via PLC."Regarding our automatic rewinding machine, the crowds appreciated the functional adjustment that enables keep the coil diameter constant despite any tolerance or adaptation of the “mother” film so to deliver a product exactly in-line with the expectations of the customers and the target market.”

EMERGENZA CORONAVIRUS: comunicazione a tutti i Clienti e Fornitori

A seguito delle ulteriori misure restrittive di contenimento al contagio COVID 19 messe in atto con il decreto del Presidente del Consiglio dei Ministri del 22/03/2020, UNITECH srl ha predisposto la chiusura totale della sede di Vigevano (PV) dal 23/03/2020 al 05/04/2020.

Sono sospese in tale periodo tutte le attività produttive, logistiche, amministrative, di manutenzione esterne e di qualsiasi altro carattere aziendale.

Auguriamo che questa drammatica situazione possa risolversi nel più breve tempo possibile e che si possa tornare insieme a guardare con grande ottimismo al futuro, per lo sviluppo costante della nostra attività e di quella dei nostri Partner.

Siamo raggiungibili ai seguenti contatti in smart working:

Comunicazioni generali e commerciali – info@unitechpackaging.com

Tecnico – tecnico@unitechpackaging.com

Assistenza – support@unitechpackaging.com

Amministrazione – amministrazione@unitechpackaging.com

Cordialmente

CORONAVIRUS EMERGENCY: communication to all Customers and Suppliers

Following the further restrictive measures to contain COVID 19 contagion implemented with the Government decree of 22/03/2020, UNITECH srl has closed his headquarter in Vigevano (PV) from 23/03/2020 to 05/04/2020.

All Production, Logistic, Administrative and External Maintenance are suspended in this period.

We hope that this dramatic situation can be solved in the shortest possible time and that we can return together to look to the future with great optimism, for the constant development of our activity and of his Partners.

We are at your disposal in smart working at the following contacts:

General and commercial – tecnico@unitechpackaging.com

Tecnical – tecnico@unitechpackaging.com

Support – support@unitechpackaging.com

Administration – amministrazione@unitechpackaging.com

Kind regards

Close