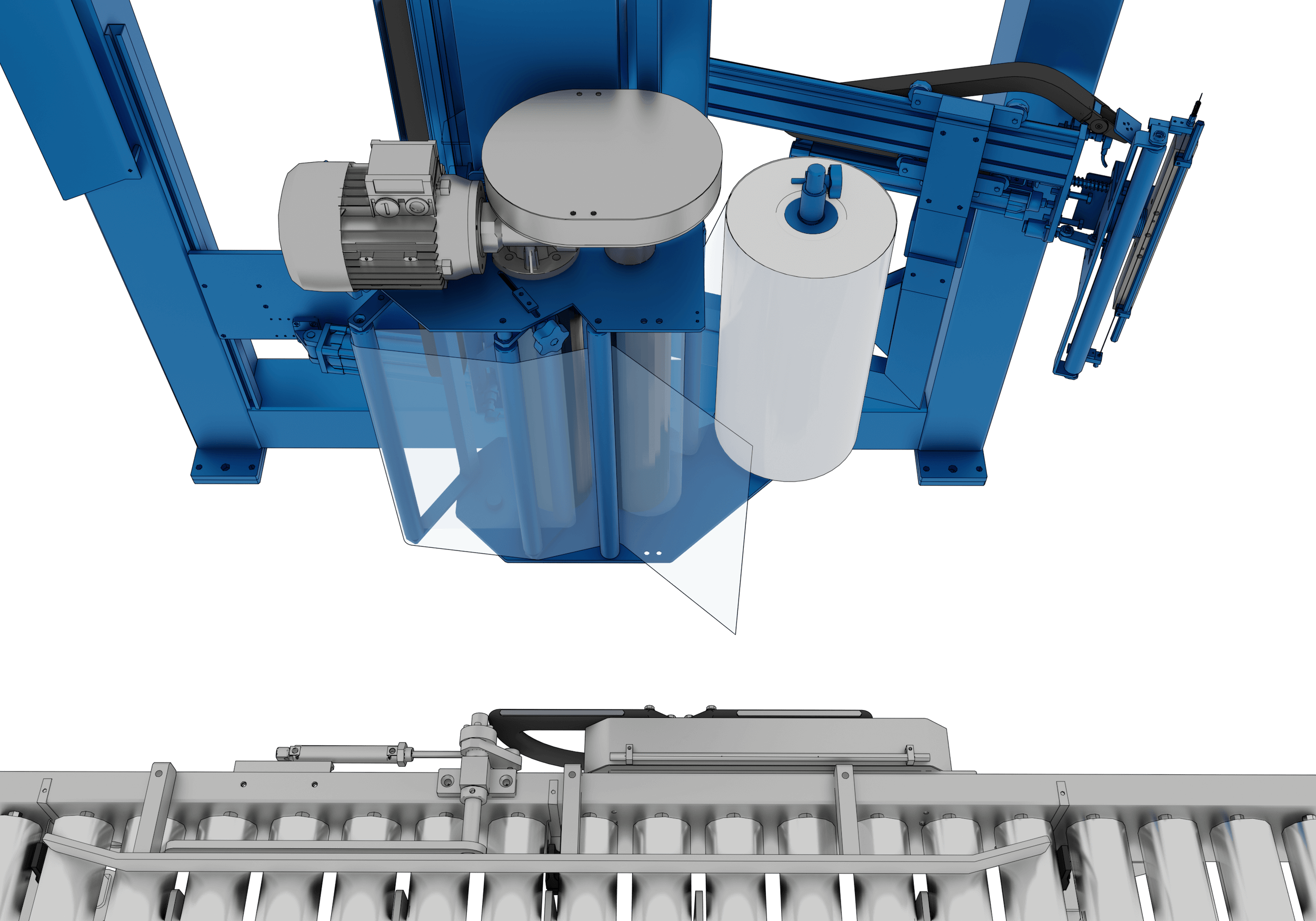

UNIWRAP 300 Auto

Automatic wrapping machine with arm rotation

to stretch-wrap palletised loads

Durable

Made to last and to minimize the impact of maintenance

Efficient

Crafted to maximize cost effectiveness and minimize the impact on the enviroment

Production

72 pal/h

Leggi di più

Pallet dimension 1.200 mm x 800 mm x height 1,600 mm , with 9 wrapping turns, 500 mm fim height, conveyor speed 15 mt / min, stable load

- Dispositivi consigliati

- Electronic powered pre-stretch with duble motors

mod. PE/2RM (film height mm. 500) with adjustable ratio directly from the control panel and adjustable tension of the stretch film on the corner of the load

- Pneumatic device installed on the pre-stretch

dispensing arm to adjust stretch film tension on the load during the wrapping cycle; all possible settings of the wished pressure are activated by proportional valve controlled by PLC

- Electropneumatic welding unit by contra-plate

no contact with the load

- Modem for remote assistance via Internet

with safe VPN internet connection

- Opzioni aggiuntive

- Pneumatic / mechanical top pressor

for light or unstable products

- Electronic powered pre-stretch unit with fix ratio

mod. PE/1RMI (film height mm. 500) and adjustable tension of the stretch film on the corner of the load (max. pre-stretch value 260%)

- Electropneumatic welding unit with integrated cutt

directly on the palletised load

- Hydraulic lifter

for the complete wrapping of the wooden pallet installed under the powered rolls conveyor

- Device to reduce stretch film height

in order to create a “pre-stretched rope” and apply it on the layers of the load as an horizontal strap or directly on the pallet wood to secure load on it; the system will be controlled by PLC and may be excluded directly from operating panel

- Device to cut stretch film width into 3 stripes

and wrap the pallet in order to create an “anti-condensation packaging”; the system is controlled by PLC and may be excluded directly from operating panel

- Weighing system to be installed under conveyor

Nr. 4 weighting cells with supporting plates

Nr. 1 net device between the 4 weighting cells

Nr. 1 electronic display to show weighting data (without data transmission)

Nr. 1 push-button for pallet exit / confirmation that data have been read P39"

Build the way you need! literally

Designed to meet the needs of each customer (possible line example)