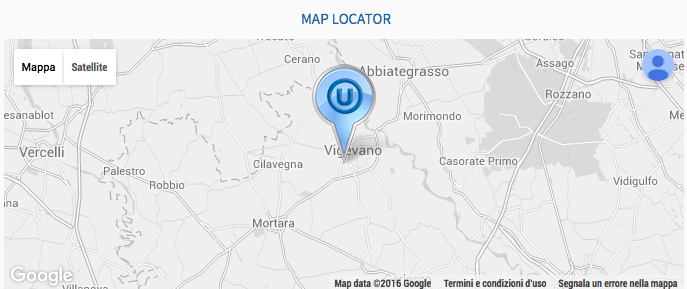

Unitech T012R automatic rewinding machine

Unitech T012R is an automatic rewinding machine to rewind stretch film rolls with core and without pre-stretching.

The automatic rewinding machine, model T012R, works at the maximum speed of

1300 m/min, produces standard stretch film rolls WITH CORE.

The rewinding process is made on a station complete with automatic loading of the

core, stretch film cutting and exit of the rewinded roll on a po wered belt conveyor

positioned at the outfeed.

The HMI (touch screen) and all the control devices (such as pre ssure regulators) are

installed on the structure of the machine for an easy and immediate use.

Main operative items:

- The rewinding process is done in contact with a powered roll wi th adjustable speed

- up to 1300 m/min.

- The rewinding tension is adjustable and controlled by PLC.

- The rewinding process is made on a station with automatic control of the pressure

- of the reel on the rewinding roll driven by propor tional pneumatic valve.

- Maximum standard Ø of the rewinded roll is 250 mm, with automat ic change at

- the end of the rewinding cycle, film cutting and star t of a new rewinding process.

- Automatic core loader complete with core magazine (capacity 70 cores Ø 76-

- 150 cores Ø 50).

- Pair of mandrels with Ø 50 or 76 mm.

- Pneumatic moving arms to load feed stretch rolls, installed on the back side of th e

- machine; the feed roll is pneumatically centered by two mandrel s (Ø 76 mm).

- Jumbo roll size: Maximum Ø 450 mm; Maximum width 600 mm.

- Main control board run by PLC.

- Operating touch screen panel complete with digital display to c ontrol:

- Autodiagnosis program and visualisation of the alarms.

- Selection of manual operation.

- Settings of the rewinding cycle (possible of setting up to 20 p rograms).

TECHNICAL DATA:

- Stretch film thickness of the feed roll: 8 up to 35 my.

- Maximum Ø of the rewinded rolls: mm 250.

- Power supply: 400/480 V – 3ph + W

- Power consumption: 11 kW.

- Compressed air supply: 6-7 bar.

- Automatic device to detect holes in the stretch film by electron ic card and visual/

- audible alarm without stopping the machine.

- Automatic detection of the end of the feed roll by photocell wi th automatic

- machine stop when last roll has been rewinded.

- Rewinding speed: max 1300 m/min.

- Rewinding speed depends on quality of the stretch film used.